Industrial and infrastructure processes are normally monitored by computers or PLC. SCADA and HMI are control systems that are used in any organization. At different levels they are the interface between the plant or machinery and its operator. They are important factors when interacting with any process control.

WHAT IS A HMI?

A HMI (Human Machine Interface), is a device or software that allows its user to communicate with machineries and production plants in a graphical way. HMIs communicate with Programmable Logic Controllers (PLCs) and input/output sensors to get and display information for users to view. HMI screens can be used for a single function, like monitoring and tracking, or for performing more sophisticated operations, like switching machines off or increasing production speed, depending on how they are implemented.

WHAT IS A SCADA?

SCADA (Supervisory Control and Data Acquisition) is a system of software and hardware elements that allows industrial organizations to control industrial processes locally or at remote locations; monitor, gather, and process real-time data; directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software; record events into a log file

What is the Difference Between HMI and SCADA?

Supervisory Control and Data Acquisition (SCADA) and HMI are closely related, and often referred to in the same context since they are both part of a larger industrial control system, but they each offer different functionality and opportunities. While HMIs are focused on visually conveying information to help the user supervise an industrial process, SCADA systems have a greater capacity for data collection and control-system operation.

OUR HMI AND SCADA SOFTWARE ENGINEERING

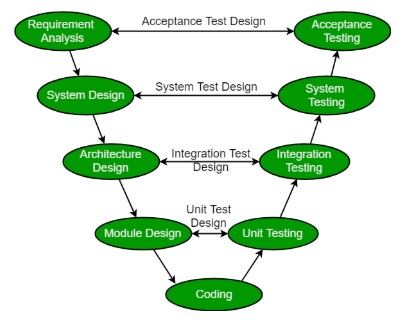

Our experience from the automotive industry and from the military environment produces robust, functional and user-friendly HMI and SCADA applicationsdesigned to satisfy your requirements. We extensively use the V-Model in software engineering . The V-model is an SDLC (Software Development Life Cycle) model where execution of processes happens in a sequential manner in a V-shape. It is also known as Verification and Validation model. The V-Model is based on the association of a testing phase for each corresponding development stage.

This process uses simulation techniques to develope, validate, test and demonstrate plant system operations to satisfy requirements before starting building the control system, which enables to identify issues with the design and to rectify them reducing the cost of development.

Our software engineering is supported by:

- Software in loop simulation (SIL)

- Hardware in loop simulation (HIL)

- Proof of concept on our in house test rig

All the activities of simulation and testing are designed to make sure tha we pass the Factory Acceptance Testing (FAT) to verify that the new control system will operate to satisfy our customers requirements.

HMI software tools we have used in real projects:

The following section shows our extensive experience with HMI software tools. We are not limited only to our past experience and we welcome to use different brands should be required by the project specifications:

- Galileo

- Beckhoff

- Red Lion

- Visual Studio

- Visual C++

- C#

SCADA software tools we have used in real projects:

The following section shows our extensive experience with SCADA software tools. We are not limited only to our past experience and we welcome to use different protocols should be required by the project specifications:

- Indusoft

- Zenon