What is Automation in Industrial Manufacturing and Process Control?

Automation takes a step further mechanization that uses a particular machinery mechanism aided human operators for performing a task. Mechanization is the manual operation of a task using powered machinery that depends on human decision making.

Industrial Automation is the replacement with computers and machines to that of human thinking. The word Automation gives the meaning ‘self dictating’ or ‘a mechanism move by itself’ that derived from the Greek words Auto and Matos where auto means self while Matos means moving.

Our industrial automation services use of set technologies, automatic control devices, process control and control system techniques that results the automatic operation and control of industrial processes without significant human intervention and achieving superior performance than manual control.

Why Industrial Automation and Process Control with us?

- To increase productivity

Our automation of factory or manufacturing or process plant improves production rate through a better control of production for you. It helps you to produce mass production by drastically reducing assembly time per product with a greater production quality. Therefore, for a given labor input it produces for you a large amount of output.

- To provide optimum cost of operation

Our integration of various processes in your premises with automated machinery, minimizes cycle times and effort and hence maximizes the return of your investment. Preventative maintenance approach, IoT (Internet of Things) and AI (Artificial Intelligence) will eliminate the need of costly routine maintenance. Also, it eliminates the risk of manufacturing shutdown, which it prevents lost income due to production downturns.

- To improve product quality

Since our automation solutions reduce the human involvement, the possibility of human errors also gets eliminated. We will enable you to achieve uniformity and product quality with a greater conformity which can be maintained with automation by controlling and monitoring the industrial processes in all stages right from inception of a product to an end product.

- To reduce routine checks

Our automation solutions completely reduce the need for manual checking of various process parameters. By taking advantage of our automation technologies, your industrial processes automatically adjusts process variables to set or desired values using closed loop control techniques.

- To raise the level of safety

Our approach is always to priorities corporate wellbeing in terms of safety, health and avoiding operators soft tissue injuries. Industrial automation increases the level of safety to personnel by substituting them with automated machines in hazardous working conditions. Traditionally, industrial robots and robotic devices are implemented in such risky and hazardous places.

Projects:

We manage project and handle any design and development activities with the military style approach, which we gained in past experience in the defense sector. So, project fail is not an option.

We design and develop PLC software and Windows applications with the V-Model approach, which we gained in past experience in the automotive sector. So, software bugs are not an option.

We also value human interaction and corporate wellbeing. So, safety and avoiding operators soft tissue injuries are always in our mind.

Duties include:

- Project management from requirement gathering to aftermarket technical support

- Project audit and rescue

- Machinery safety and EMC compliance

- Process control and functional safety

- Power generation automation

- Fire unit systems

- Ergonomics and Soft Tissue Injury Prevention

- m2m applications

- Automation and control systems for power stations

- Embedded systems and virtual instrumentation

- Manufacturing and factory automation

- Building automation

- Remote monitoring and remote technical support

- PLC, HMI and SCADA systems

Manufacturing automation projects:

- Timber trusses manufacturing automation

- Crate wash plant automation

- Farm irrigation automation

- Door skin manufacturing automation

- Drum oil filling station automation

Power generation projects:

- Tri-generation plant automation

- Wind farm automation

- Fuel pumping system automation for backup power generation

Machinery projects:

- CNC Machines and Machinery design

- Machinery Repairing, Safety and EMC (Electro Magnetic Compatibility) compliance

- Fire protection

- Machinery ergonomics and operator soft tissue prevention

- Remote technical support and troubleshooting

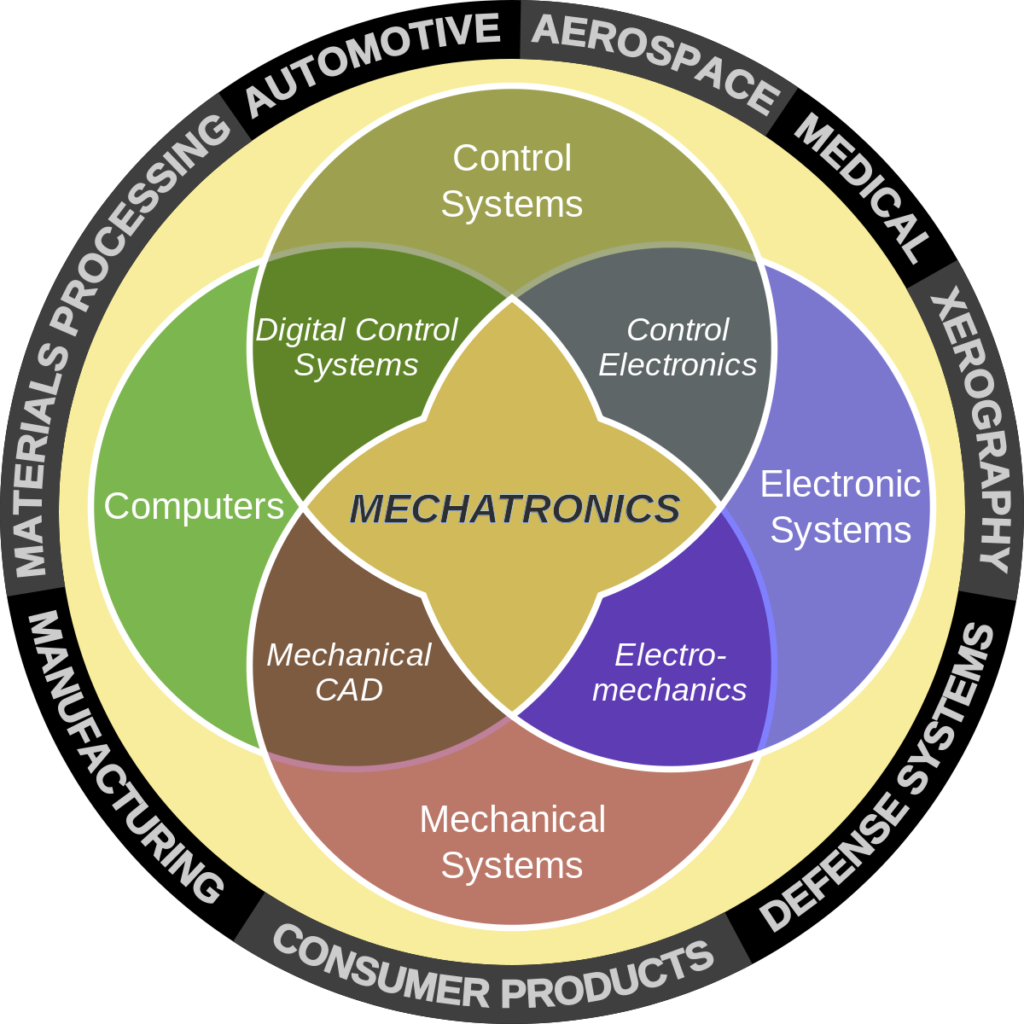

Mechatronics projects:

- Electronic design and manufacturing of vending controllers

- Electronic design and manufacturing of GSM (Global System for Mobile) controllers

- Application software development for vending controllers and GSM controllers

- Remote monitoring and control using GSM controllers

DO YOU NEED ENGINEERING SUPPORT FOR YOUR MANUFACTURING AND PROCESS CONTROL? ARE YOU LOOKING TO SEEK THE SOLUTION TO YOUR PLANT CHALLENGES?

Contact DAE AUTOMATION today for project audit and rescue services with more than 25 years’ industry experience. Melbourne based with services available Australia-wide for remote and on-site projects.