Mechatronics is a multidisciplinary field of science that integrates the principals of mechanical engineering, electronics, computer engineering, telecommunications engineering, systems engineering and control engineering into a unified discipline while integrating embedded systems into mechanical components.

WHAT IS AN EMBEDDED SYSTEM?

An embedded system is a computer system—a combination of a computer processor, computer memory, and input/output peripheral devices—that has a dedicated function within a larger mechanical or electrical system.

It is embedded as part of a complete device often including electrical or electronic hardware and mechanical parts. Because an embedded system typically controls physical operations of the machine that it is embedded within, it often has real-time computing constraints. Embedded systems control many devices in common use today. Ninety-eight percent of all microprocessors manufactured are used in embedded systems.

Modern embedded systems are often based on microcontrollers (i.e. microprocessors with integrated memory and peripheral interfaces), but ordinary microprocessors (using external chips for memory and peripheral interface circuits) are also common, especially in more complex systems. In either case, the processor(s) used may be types ranging from general purpose to those specialized in a certain class of computations, or even custom designed for the application at hand. A common standard class of dedicated processors is the digital signal processor (DSP).

Since the embedded system is dedicated to specific tasks, design engineers can optimize it to reduce the size and cost of the product and increase the reliability and performance. Some embedded systems are mass-produced, benefiting from economies of scale. Below is an example of embedded system we designed for a vending application:

WHAT DO WE DO?

As Mechatronics engineers we can work in all aspects of the development of products, from design and testing right through to manufacture. We can also design test rigs and virtual instrumentation to assist with validation process. There is almost no product in the world that is solely electronic, electrical or mechanical in nature. With the growing capabilities of electronics, modern mechanical systems are embedded with electronics and controls.

From consumer goods, such as microwaves, cars and smart phones, to industrial applications such as CNC machine tools, robots and MRI and X-Ray machines, we use fundamental principles of electrical, mechanical, software, and control engineering in their design and development in order to generate a simpler, more economical and reliable way to do things.

We can help to create machines that are made up of several parts: the mechanical system, the sensing and actuation, the control systems and the software. Also we can undertake:

- Develop solutions to industrial problems by using mechanical/electronic/computer technology

- Design and build new products – for example, developing robotic vehicles for underwater exploration

- Introduce automation to factory production lines to improve existing processes

- Improve previous industrial/manufacturing processes – for example, robotic floor cleaners

- Design and develop engineering systems for the automation of industrial tasks

- Apply mechatronic solutions to the transfer of material, components or finished goods

- Apply control systems which are typically computer-driven

- Apply electronic/mechanical processes and computers to dangerous tasks in underwater exploration, mining or forestry

- Study the feasibility of new mechatronic equipment

- Carry out modelling and analysis of mechanical, electronic or other systems using computers

- Embedded systems programming

OUR SOFTWARE ENGINEERING

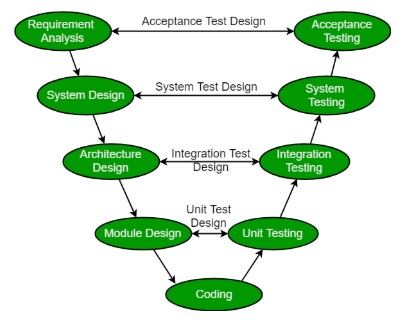

Our experience from the automotive industry and from the military environment produces robust, functional and user-friendly programs designed to satisfy your requirements. We extensively use the V-Model in software engineering . The V-model is an SDLC (Software Development Life Cycle) model where execution of processes happens in a sequential manner in a V-shape. It is also known as Verification and Validation model. The V-Model is based on the association of a testing phase for each corresponding development stage.

This process uses simulation techniques to develope, validate, test and demonstrate plant system operations to satisfy requirements before starting building the control system, which enables to identify issues with the design and to rectify them reducing the cost of development.

Our software engineering is supported by:

- Software in loop simulation (SIL)

- Hardware in loop simulation (HIL)

- Proof of concept on our in house test rig and virtual instrumentation

All the activities of simulation and testing are designed to make sure tha we pass the Factory Acceptance Testing (FAT) to verify that the new mechatronics system will operate to satisfy our customers requirements.

Protocols we have used in real projects:

The following section shows our extensive experience with embedded communication protocols. We are not limited only to our past experience and we welcome to use different protocols should be required by the project specifications:

- FlexRay

- TTP

- CAN

- CCP

Software tools we have used in real projects:

The following section shows our extensive experience with mechatronics software tools. We are not limited only to our past experience and we welcome to use different languages should be required by the project specifications:

- Solidworks

- AutoCAD

- Altium Designer

- Matlab (Microchip)

- LabVIEW (Virtual instrumentation)

- MPlab (Freescale)

- Code Composer (Texas Instrument)

- C/C++