WHAT IS A PLC?

A PLC (Programmable Logical Controller) is an industrial computer control system that continuously monitors the state of input devices, makes decisions based upon a custom program to control the state of output devices. … Another advantage of a PLC system is that it is modular.

By using robust software engineering, a A well-programmed PLC can automate plant operations and process control in a smart and safe way, while enabling easy diagnostics and remote monitoring with remote technical support.

PLC development tools are fully comprehensive software platform for industrial automation technology. The platform could be based on IEC 61131-3 programming tool. They provide end users with extensive integrated solutions for convenient project engineering of automation applications. The associated goal is to provide practice-oriented support for users in the implementation of their tasks.

OUR PLC SOFTWARE ENGINEERING

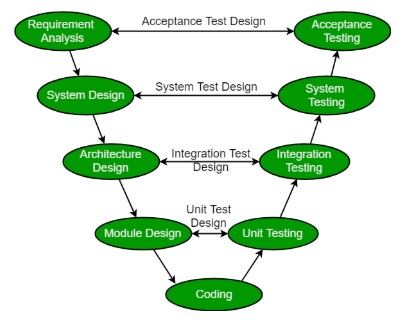

Our experience from the automotive industry and from the military environment produces robust, functional and user-friendly programs designed to satisfy your requirements. We extensively use the V-Model in software engineering . The V-model is an SDLC (Software Development Life Cycle) model where execution of processes happens in a sequential manner in a V-shape. It is also known as Verification and Validation model. The V-Model is based on the association of a testing phase for each corresponding development stage.

This process uses simulation techniques to develope, validate, test and demonstrate plant system operations to satisfy requirements before starting building the control system, which enables to identify issues with the design and to rectify them reducing the cost of development.

Our software engineering is supported by:

- Software in loop simulation (SIL)

- Hardware in loop simulation (HIL)

- Proof of concept on our in house test rig

All the activities of simulation and testing are designed to make sure tha we pass the Factory Acceptance Testing (FAT) to verify that the new PLC program will operate to satisfy our customers requirements.

PLC EXTENDED CAPABILITY:

There are situations where the PLC reaches its limit, like communicating to a protocol which does not follow any industrial standard [e.g. Microsoft Inter-Process Connectivity (IPC)]. Our PLC software engineering achieves to extend PLC capabilities by using high level languages like C#.

Brands we have used in real projects:

The following section shows our extensive experience with PLC brands. We are not limited only to our past experience and we welcome to use different brands should be required by the project specifications:

- Beckhoff

- Eaton

- Codesys

Protocols we have used in real projects:

The following section shows our extensive experience with PLC communication protocols. We are not limited only to our past experience and we welcome to use different protocols should be required by the project specifications:

- Modbus

- KNX

- DMX

- Ethernet IP

- Ethercat

- OPC

- CAN

Languages we have used in real projects:

The following section shows our extensive experience with high level languages to expand the PLC languages. We are not limited only to our past experience and we welcome to use different languages should be required by the project specifications:

- IEC 61131-3

- C#

- Visual Studio